Remanufacturing CS-400E Cut & Clinch Machine

STEP 3: Rebuild Subassemblies

3.2 Projector and Microscope Subassemblies

- Subassemblies are disassembled down to the component state.

- Every part is cleaned and re-lubricated if required.

- Faulty or worn parts are replaced.

- The subassemblies are rebuilt to original manufacturing standards.

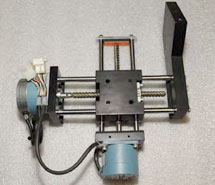

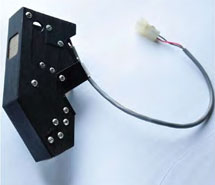

Below you can see two examples of remanufactured subassemblies.

Projector Assembly |

|

|

|

disassembled |

remanufactured |

Optical Correction Microscope Assembly |

|

|

|

old unit disassembled |

remanufactured |

Click here to see side-by-side images of the parts before and after remanufacturing.